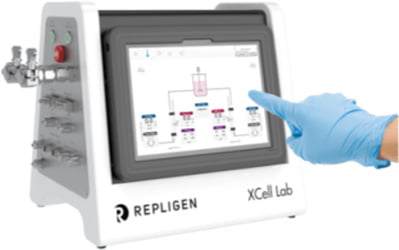

PRODUCT

ATF System

XCell® ATF Systems attach to a bioreactor to intensify

upstream manufacturing capacity, productivity, and throughput.

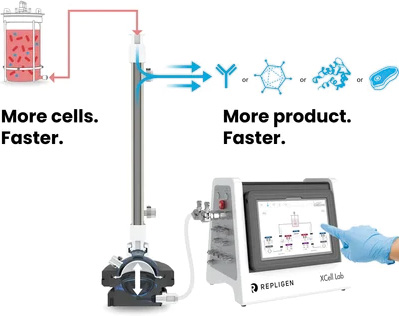

INTENSIFICATION DELIVERS MORE PRODUCT FASTER

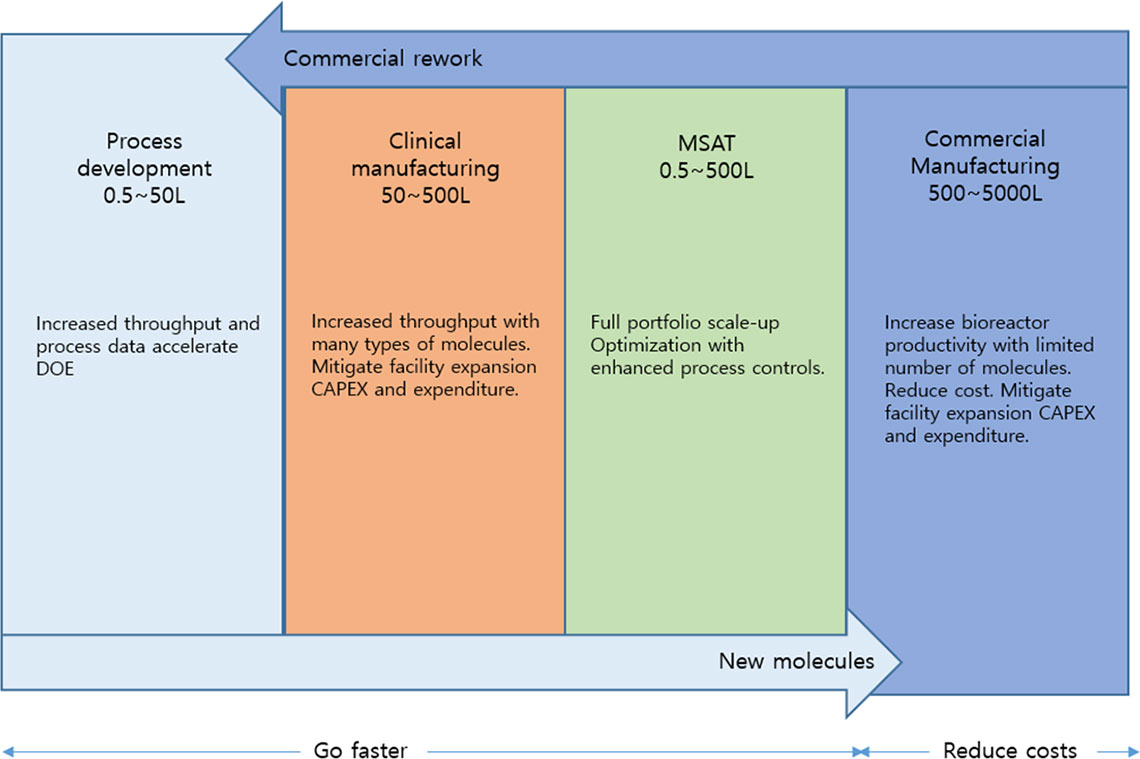

XCell ATF Technology helps simplify and intensify upstream processes to deliver more product, faster. Intensified processes achieve higher cell densities,

require smaller bioreactors and consume less suite time. Increase throughput, productivity, and capacity in both clinical and commercial manufacturing.

HOW XCell ATF® TECHNOLOGY WORKS

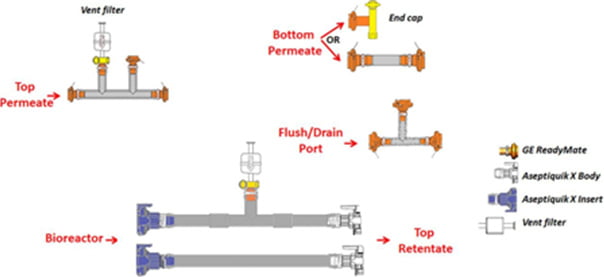

The XCell ATF System is based on award-winning alternating tangential flow (ATF) technology, created by the action of a diaphragm moving upward and downward within a pump head, connected to a filter housing and attached to a bioreactor. Alternating tangential flow is attained by the action of a diaphragm pump.